DOWNLOAD PNEUMATIC PRINTING MACHINE PROJECT REPORT | Get Mechanical Engineering Project Ideas for study and research. we Mechanical Farm provide the widest list of Mechanical engineering projects topics to help students, researchers & engineers in their R&D. Also, we have a great variety of pre-made project kits using hydraulics, gears, energy generation systems for you to use in your projects.

Table of Contents

DOWNLOAD PNEUMATIC PRINTING MACHINE PROJECT REPORT:

INTRODUCTION

The pneumatic system has gained a large amount of importance in last few decades. This importance is due to its accuracy and cost. This convenience in operating the pneumatic system has made us to design and fabricate this unit as our project. This unit, as we hope that it can be operated easily with semi skilled operators.

The PNEUMATIC PRINTING MACHINE has an advantage of working in low pressure, that is even a pressure of 6 bar is enough for operating the unit. The pressurized air passing through the tubes to the cylinder, forces the piston out whose power through the linkage is transmitted to the tool . The work piece thus got is for required dimensions and collected through the provided in the printing pad tool .

The tool is used in this is fixed such that the material gets required shape can be used according to the requirement. This enables us to use different type media fro printing pad resulting in a wide range of products. Different types of printing pad tools as requirement can be thus got. According to the work material the operating pressure can be varied.

The designer should make the machine as reliable as reasonably possible to minimize the maintenance requirement and allow for long intervals between routine maintenance tasks. It is also important to design the machine and its control system so that maintenance can be carried out safely.

For example, hold-to-run controls can be installed that allow a machine to be run at a reduced speed, or removable tool holders can be used so that sharp blades can be replaced on a workbench instead of in an difficult position inside a machine. In addition, operators and maintenance technicians must be discouraged from bypassing safety equipment.

Safety components are often designed to interrupt processes in the event of a fault and will have an impact on machine availability. In order to minimize this effect – and the temptation to interfere with the safety circuits – high-reliability safety components should be specified so as to keep the number of nuisance faults at a minimum. Designing safety into a new machine is important, but it has to be remembered that the vast majority of machines do not remain unaltered, with unchanged operating procedures, for their entire lifetime.

How a printing press works?

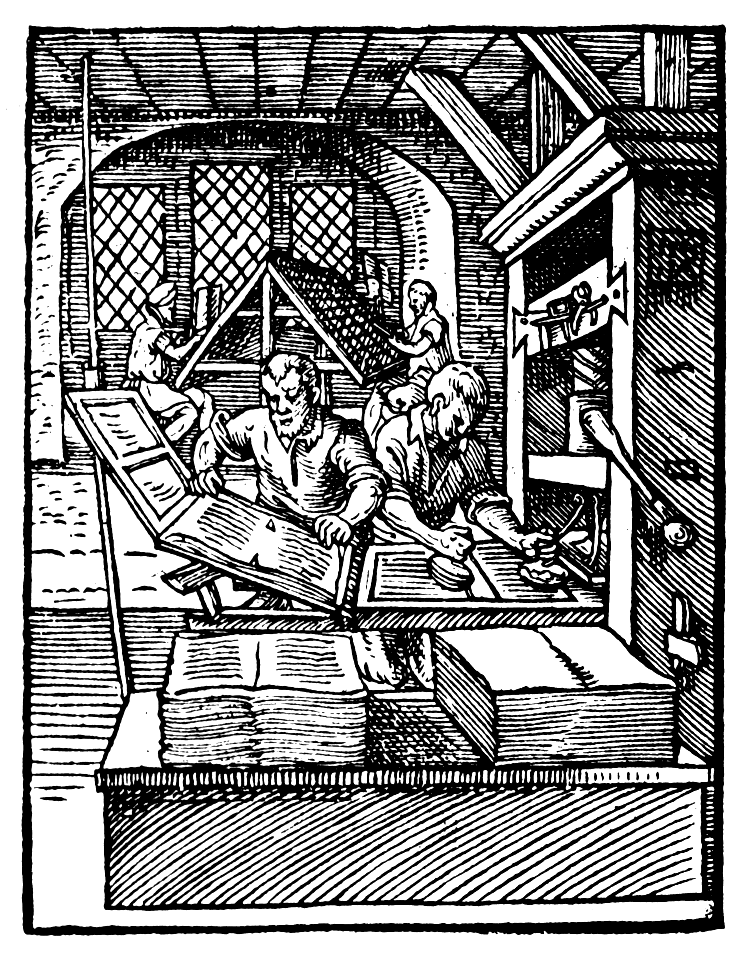

This woodcut from 1568 shows the left printer removing a page from the press while the one at right inks the text-blocks. Such a duo could reach 14,000 hand movements per working day, printing around 3,600 pages in the process.

A printing press, in its classical form, is a standing mechanism, ranging from 5 to 7 feet long, 3 feet wide, and 7 feet tall. Type arranged into pages is placed in a frame to make a forme, which itself is placed onto a flat stone or ‘bed’. The type is inked, and the paper is held between a frisket and tympan (two frames covered with paper or parchment). These are folded down, so that the paper lies on the surface of the inked type. The bed is rolled under the platen, using a windlass mechanism, and the impression is made with a screw that transmits pressure through the platen. Then the screw is reversed, the windlass turned again to move the bed back to its original position, the tympan and frisket raised and opened, and the printed sheet removed. Such presses were always worked by hand. After around 1800, iron presses were developed, some of which could be operated by steam power.

| Pneumatic and Hydraulic based Engineering Projects |

| Pneumatic Projects |

| Pneumatic and Hydraulic Projects |

Hello sir/Ma’am , I am a BE Mechanical Student in 2nd year, we have a group project on any mechanical engineering topic but we all are very confused , so we need a suggestion of making a mini Project with low cost …

Hello Aniket, Here are few mini Project topic lists. Please go through them:

{70+Updated} Best Mechanical Mini Projects List 2021

Low Cost Mini Projects For Mechanical Engineering Students

Hello I want new mechanical final year project?

I am second year mechatronics student and I really a project for my are of study